PUR Coating and Film Laminute Line

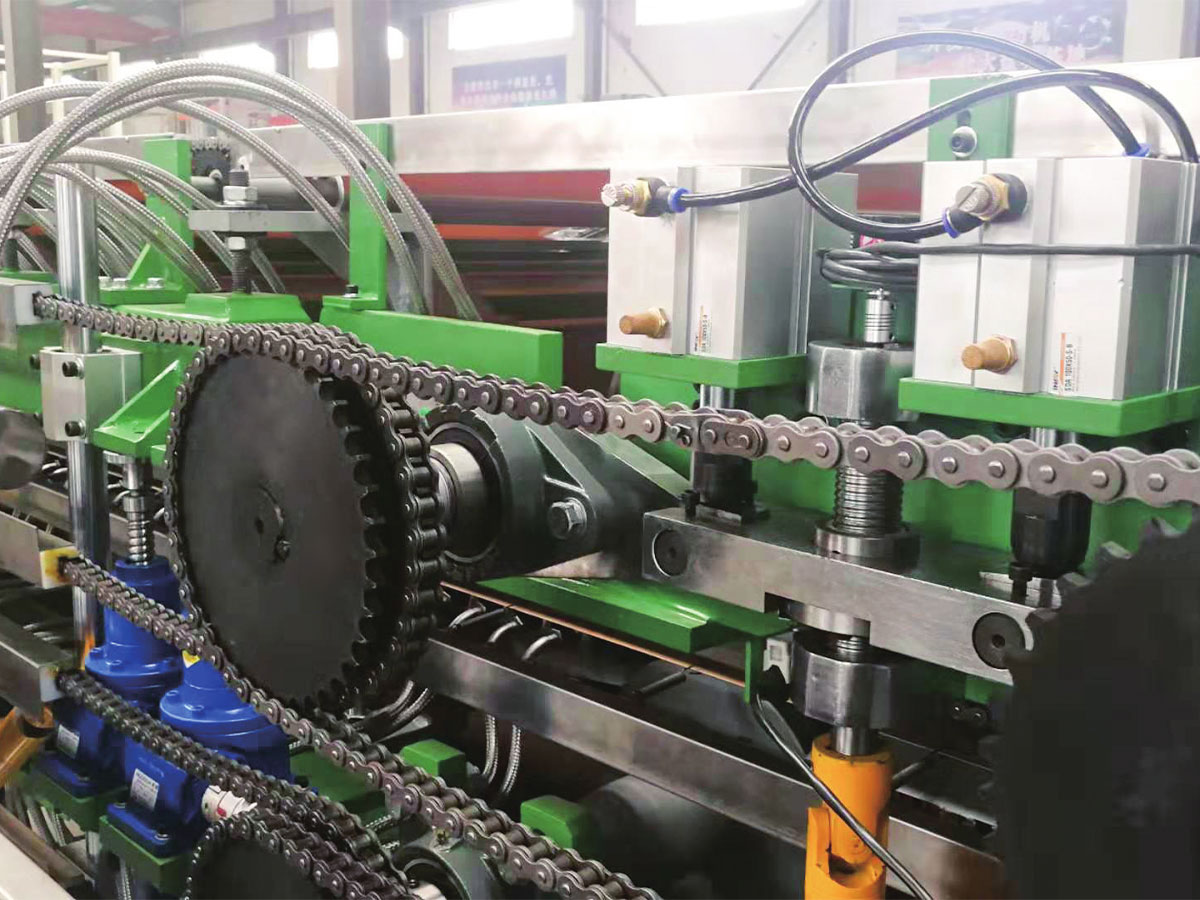

The PUR coating and laminating line is primarily used for high-strength lamination of various functional films (such as decorative films, protective films, and functional films) onto various substrates (metal, plastic, and wood). The PUR coating and laminating line utilizes polyurethane reactive hot melt adhesive (PUR), which forms an irreversible cross-linking structure upon moisture curing, providing bond strength and durability far exceeding that of conventional hot melt adhesives. This line can handle a wide range of substrate and film combinations, including metal, plastic, wood, and glass, meeting the lamination needs of diverse industries. The laminated surface is smooth, bubble-free, and has a clear texture, perfectly preserving the original effects and functionality of the decorative film.

A precision metering system heats and melts solid PUR adhesive pellets into a liquid state. A slot-type coating head or roller coating device applies the adhesive to the substrate surface with precise thickness and uniformity. The pre-treated decorative or functional film is laminated to the coated substrate using a precision alignment device under the control of a tension control system. The laminating rollers apply appropriate pressure and temperature to ensure a perfect, bubble-free, and wrinkle-free bond between the film and substrate.

PUR And Film Lamination Line

This line is mainly used for applying PUR on the surface of panels for laminating film. The amount of spread can be controlled by

PLC. PUR is a new kind of environmentally friendly and fast irreversible adhesive, with the characteristics of extremely high adhesion, cold-resistant, water proof, and have adhesive effect instantly.

| Panel Width |

□1300MM □1600MM Rollers are 200mm wider than the finished panel. |

| Optional Items |

□PUR hot-melt machine □Corona treater □Static eliminator □Atomizing humidifier □Double station film releasing machine □Automatic cutting system □High speed loading stacker □High speed unloading stacker □Hydraulic lifting platform □Carrying car |

| Material | Suitable for laminating metal composite panel, fireproof panel, PVC panel, veneer, HPL, etc |

| Speed | Design speed 30m/min,Production speed 10-20m/min |

| Line Size | Normal size L: 36M W:6M H:2M, Size is adjustable according to customers’ needs |

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى