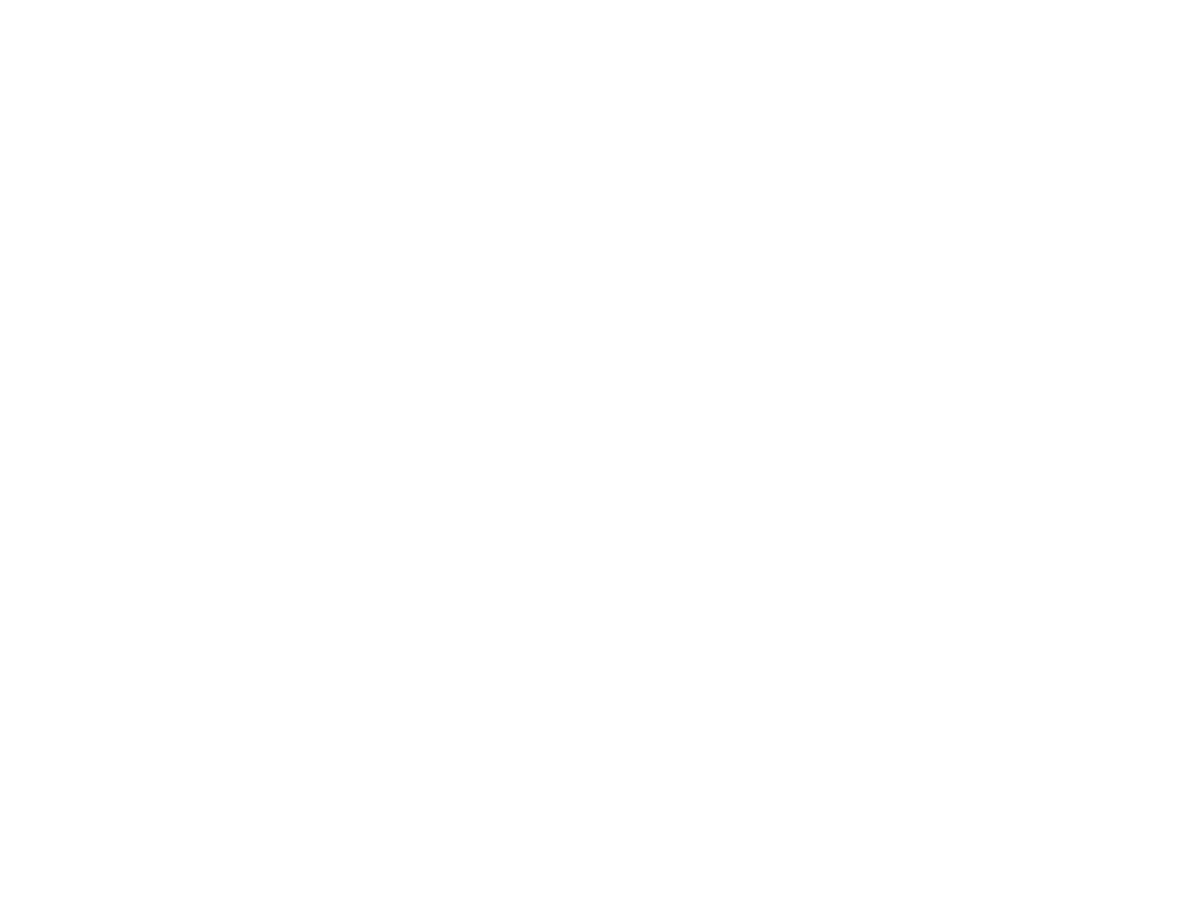

Honeycomb Panel and 3D Core Panel Composite Line

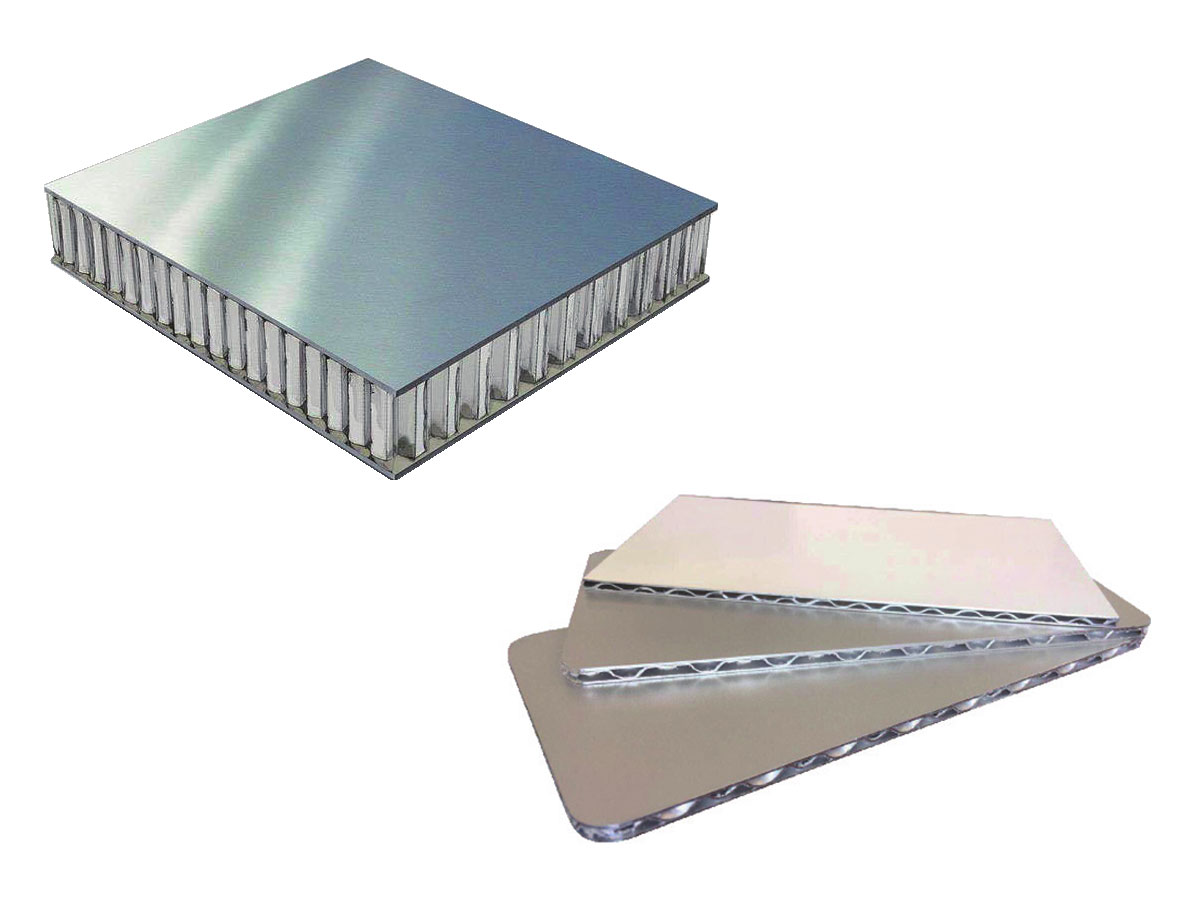

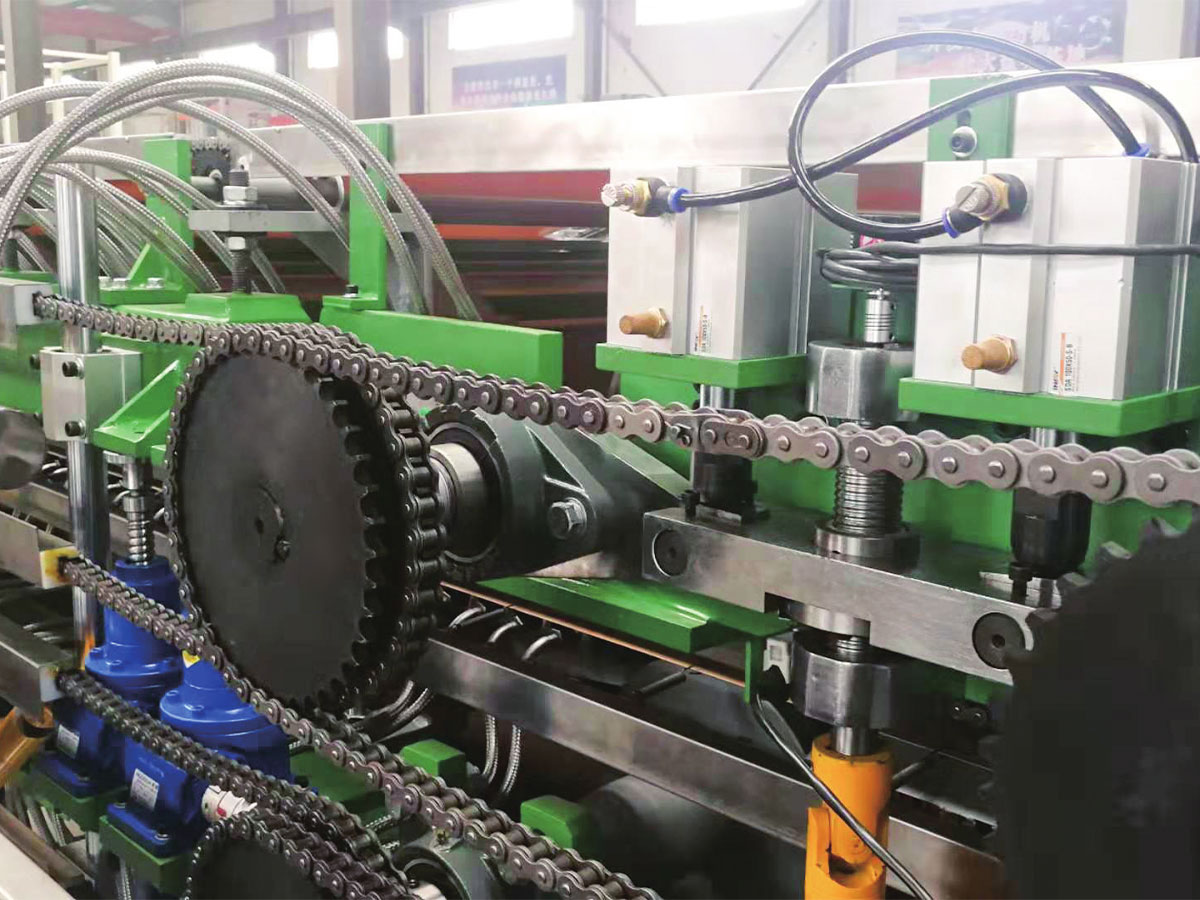

The core technology of the 3D board/corrugated board/honeycomb panel composite production line lies in its dedicated composite equipment and advanced material processing. This line uses a special polymer adhesive film as an intermediate medium to instantly laminate surface metal coils (such as aluminum, stainless steel, or galvanized steel) with a metal core material such as 3D board, corrugated board, or honeycomb panel under precisely controlled high-temperature, high-pressure conditions. Compared to traditional liquid glues, this specialized polymer adhesive film exhibits superior initial tack and ultimate bond strength. After high-temperature activation, it forms a strong bond with metal molecules, ensuring a secure and uniform bond between the core and surface materials, completely eliminating potential problems such as debonding and blistering. The adhesive film exhibits excellent resistance to aging, weathering, corrosion, and fatigue, ensuring the composite panels maintain long-term structural stability and aesthetics in a variety of harsh environments, with a service life far exceeding that of products manufactured using traditional processes.

The production line, with its modular design and intelligent program control, can rapidly switch between production lines on the same platform to produce a variety of metal-core composite panels, including three-dimensional panels (for strong decorative 3D effects), corrugated panels (for high compressive strength), and honeycomb panels (for extreme lightweighting and high flatness), truly achieving "multiple production on one line." The entire line integrates a PLC central control system and is equipped with modules such as automatic loading, precise centering, closed-loop temperature control, online monitoring, and intelligent cutting. This fully automated production process, from coil to finished product, ensures high product consistency and an extremely high yield rate.

Aluminum 3D/Corrugated/Honeycomb Panel Production Line

This is a new developed continuous production line from CJM, and it can make various types of steel core composite panels. The basic theory is to composite the steel core and steel coil by particular high polymer film through high temperature. Thus, the adhesive strength is better than traditional glue, and the durability is also improved.

| Panel Width |

□1300MM □1600MM □1800MM □2000MM Rollers are 200mm wider than the finished panel. |

| Line Type |

□3D panel series □Corrugated panel series □Honeycomb panel series □3D/Corrugated/Honeycomb panel series The above mentioned line series is different. Please contact us for more detail information. |

| Related Items |

□Automatic honeycomb core stretching machine □3D embossing machine □Corrugated embossing machine □Specialized composite machine for honeycomb panel □U type edge folding machine □Automatic stacker □Double station air expansion type uncoiler □Decorative film lamination machine □MES digital control display screen □Automatic coil centering system |

| Material |

3D core material: H0 aluminum coil, GA coil, etc. Honeycomb core material: single bar type or continuous type, regular thickness: about 6-25mm Facing material: Aluminum, Galvanized steel, Stainless steel and other metal coil. |

| Speed |

Design speed: 3.0m/min, Production speed: 2.0-3.0m/min, Slight difference may be caused by different production |

| Line Size | Normal size: L: 50M W:12M H:5.5M Size is adjustable according to customers’ needs. |

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى