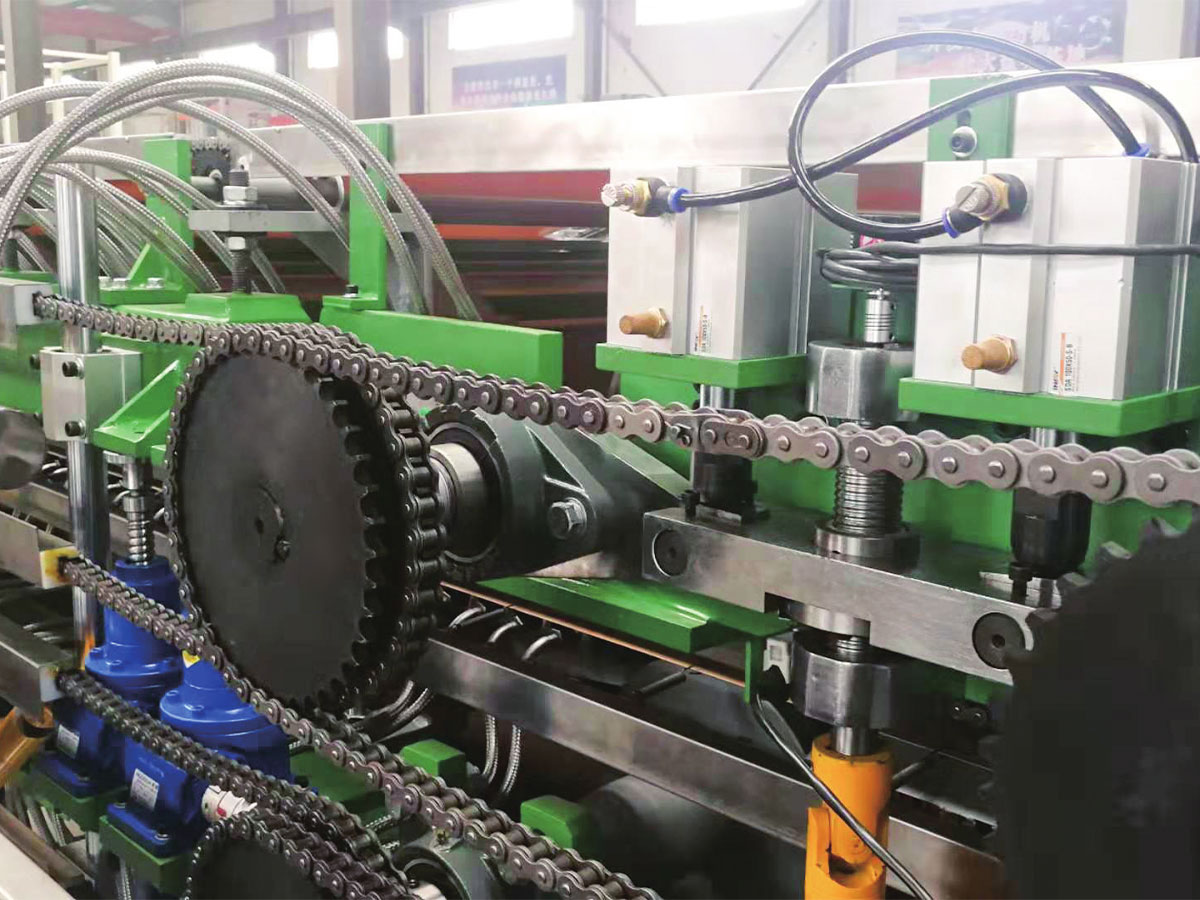

Double Metal Composite Panel Production Line

Bimetallic cladding production lines utilize advanced process technology to firmly bond two metals with different properties, creating advanced composite materials with performance far exceeding that of the individual metals.

The core technology of bimetallic cladding production lines lies in achieving a metallurgical bond between the two metals. Its main processes include but are not limited to:

Rolling cladding: This is the most widely used and continuous production method. Two pre-treated metal billets are stacked and rolled through a large rolling mill at high or room temperature, applying significant reduction. Under intense pressure, atoms at the metal interface diffuse into each other, forming a strong metallurgical bond. The resulting composite plate can then be further thinned to the desired dimensions.

Explosive cladding: Utilizing the instantaneous energy of explosive detonation, one metal plate is driven into another at extremely high speed, generating extreme pressure and heat at the collision point, thus achieving interfacial bonding. This method is particularly suitable for large, extremely thick plates or dissimilar metals that are difficult to clad.

The bimetallic plates produced by the production line utilize precious metals (such as stainless steel, titanium, nickel, and copper) only on the working surfaces where specific properties are required (e.g., corrosion resistance, electrical conductivity, and wear resistance). The substrate is constructed from lower-cost common steel (e.g., carbon steel). This design reduces precious metal usage by up to 30%-80% while maintaining performance. The metallurgical bond provides a high interface strength, preventing delamination, blistering, or shedding. The product's reliability far exceeds that of surface treatments such as coatings, extending the life of end equipment in harsh operating conditions.

Double Metal Composite Panel Production Line

This line is for compositing two different types of metal coil. The basic theory is to clean the metal coil at first, then composite by particular high polymer film under the pressure of high-temperature rollers. It has excellent peeling strength and durability.

Customers can choose to make coil product or cut to sheet with required length.

| Panel Width |

□1300MM □1600MM □1800MM □2000MM Rollers are 200mm wider than the finished panel. |

| Optional Items |

□Servo-guillotine shear system □Automatic stacker □Cantilever coil drum type uncoiler □Coil car □MES digital control display screen □Automatic coil centering system |

| Material | Copper, Aluminum, Galvanized steel, Stainless steel and other metal coil material |

| Speed | Design speed: 6.0m/min, Production speed:5.0m/min |

| Line Size | Normal size: L: 65M W:9M H:3.5M Size is adjustable according to customers’ needs. |

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى