A2 Metal Composite Panel Production Line

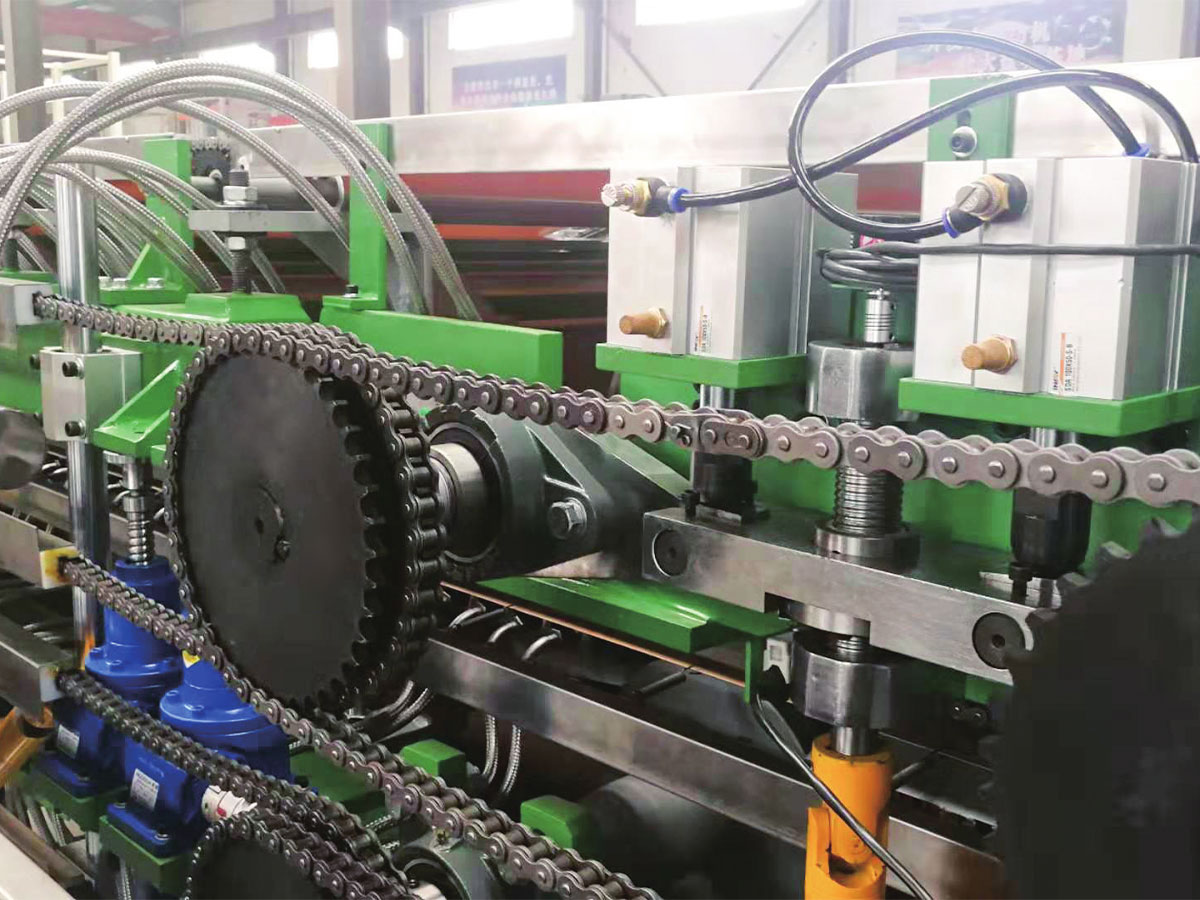

In 2012, we independently developed the A2 Metal Composite Panel Production Line, a second-generation continuous lamination line specifically designed for producing Class A fire-resistant metal composite panels.

The A2 Metal Composite Panel Production Line uses a high-temperature hot-pressing lamination process to securely bond a pre-prepared inorganic Class A2 fire-resistant core coil with upper and lower layers of metal coils (such as aluminum or galvanized steel) under high temperature and pressure. Finally, the panels are precisely cut to length to produce high-quality, uniformly sized A2 fire-resistant metal composite panels. Unlike traditional approaches, our company implemented a key innovation in the design of this production line: separating the core material production process from the lamination process. This eliminates the need for complex core material production workshops; customers can simply purchase standard A2 core coils and focus on composite panel production. This reduces overall investment in plant space and equipment, lowering both industry entry barriers and investment risks. The streamlined production line structure makes operation more convenient and easy to understand, effectively ensuring stable production and an extremely high yield rate (over 95%).

In 2019, our company launched the third-generation A2 metal composite panel production line, featuring even higher performance. Its key feature is its advanced, energy-saving infrared heating oven. This new heating method offers higher thermal efficiency and a more compact equipment layout, saving valuable production space. Compared to traditional heating methods, the third-generation line reduces energy consumption by over 50%, significantly saving customers long-term production costs and achieving significant economic benefits. It also actively supports the national call for energy conservation and emission reduction.

A2 Metal Composite Panel Production Line

This line is the 2nd generation of A2 metal composite panel production line independently developed by our company in 2012.

The basic theory is to composite aluminum and A2 class core coil under the pressure of high temperature rollers, and cut it to the required length. Meanwhile, as we are an A2 core manufacturer who has the longest history in China, we designed the production line based on the feature of A2 core. Now the yield can reach more than 95%.

In 2019, we developed the 3rd generation production line. The line is shorter(save space) and energy consumption can be reduced by 50% after adopted the new infrared ray oven.

| Panel Width |

□1600MM □1600MM □1800MM □2000MM Rollers are 200mm wider than the finished panel. |

| Oven Type |

□Heating by natural gas, hot air circulation, about 300,000kcal/h □Heating by electricity, new infrared ray type, about 100kw/h |

| Optional Items | □Servo-guillotine shear system □Automatic stacker □Double station air expansion type uncoiler □Decorative film lamination machine □MES digital control display screen □Automatic coil centering system |

| Material | Core material: A2 class fireproof core coil made by ALMINE (our company) is recommended Facing material: Aluminum, Galvanized steel, Stainless steel and other metal coil. |

| Speed | Design speed: 3.0m/min, Production speed: 2.0-3.0m/min, A slight difference may be caused by local temperature |

| Line Size | Normal size: L: 36M/50M W:12M H:5.5M Size is adjustable according to customers’ needs. |

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى