Grooving ‒ Corner Punching - Hole Punching- Edge Folding Continuous Production Line

The continuous notching-corner-trimming-punching-edge-folding production line is an integrated innovation in the sheet metal processing industry. It integrates multiple processing steps into a single automated assembly line, improving the efficiency and precision of sheet metal processing. This line is primarily designed to achieve continuous and efficient sheet metal processing, completing complex processes such as notching, corner trimming, punching, and edge folding in a single operation. It is widely used in industries such as computer chassis and cabinets, architectural decoration, furniture manufacturing, elevators, and automotive parts, meeting diverse, high-precision production needs.

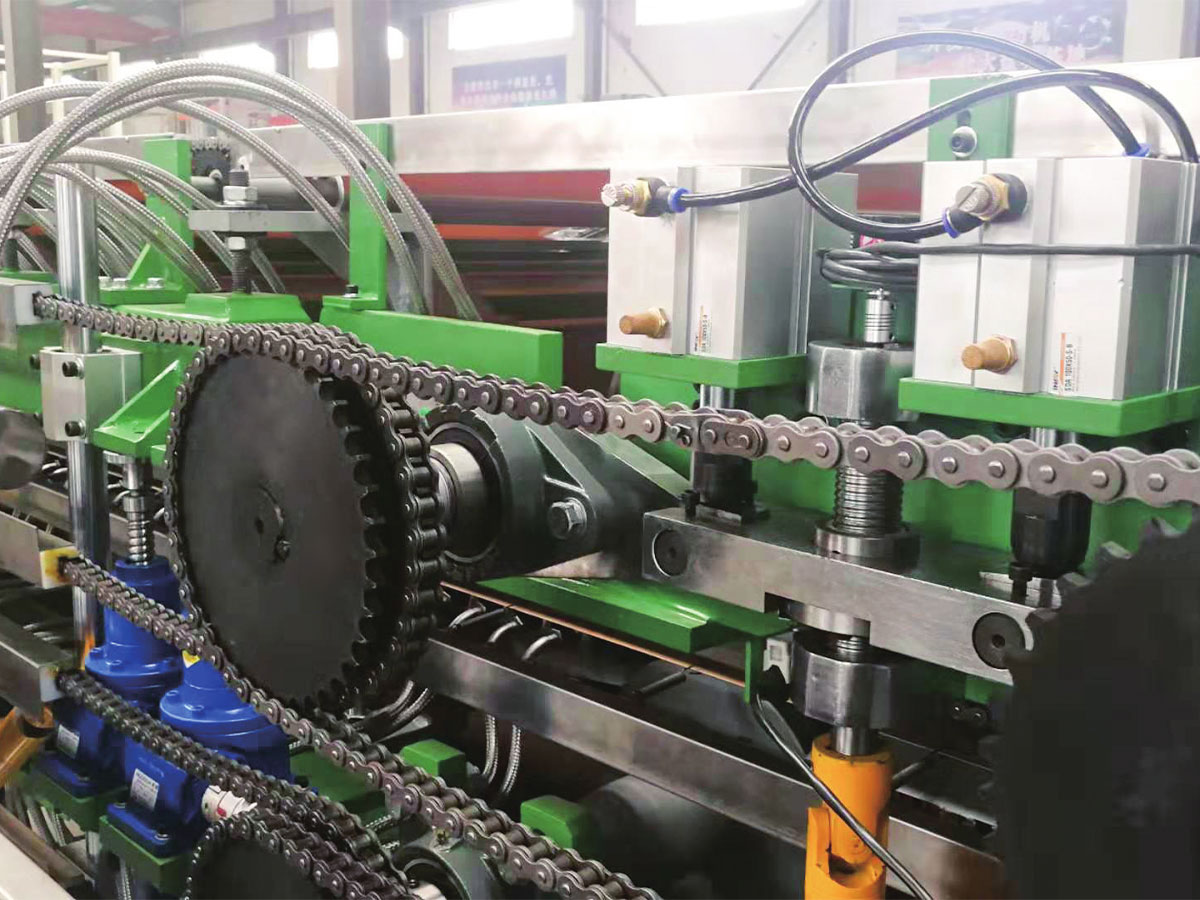

The line first accurately feeds the metal sheet into the processing area via an automatic loading system. A servo-driven precision conveyor then sequentially transports the sheet to each processing module. In the notching unit, a high-speed rotating notching cutter cuts the sheet surface according to a pre-set program, preparing it for the subsequent edge folding. The corner trimming unit uses a large die to trim the sheet edges and corners in a single operation, ensuring a smooth seam during folding. The punching unit utilizes a multi-station turret punching system to quickly and efficiently produce a variety of round, square, and special-shaped holes. Finally, the folding mechanism uses CNC control to precisely bend the sheet to form the required angle and structure.

DET Grooving ‒Corner Punching-Hole Punching-Edge Folding Continuous Production Line

This line is developed based on our decades’ experiences in ACP further processing area. It combines four sides grooving, hole punching, corner punching and edge folding functions in one line.

With daily output of more than 5000㎡, it can replace the tradition-al processing ways with 300㎡ daily output by CNC carving machine and help save labor cost for customers.

| Line Type |

□DET four sides grooving □Corner punching,hole punching □Edge Folding □Other customized |

| Panel Width |

Length □600-1300MM □600-2400MM □600-3000MM □600-4000MM Width □600-1300MM □600-1600MM □600-1800MM □600-2000MM |

| Optional Items |

□Four stations grooving □Six stations grooving □Diamond saw blade □High speed loading stacker □ High-speed unloading stacker □Hydraulic lifting platform □Carrying a car |

| Material | Thickness 3-25mm: aluminum composite panel, A2 class metal composite panel, aluminum honeycomb/3D composite panel, etc. |

| Speed | Design speed 7m/min,Production speed 5-6m/min |

| Line Size | Normal size L: 28M W:17.5M H:2M, Size is adjustable according to customers’ needs |

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى