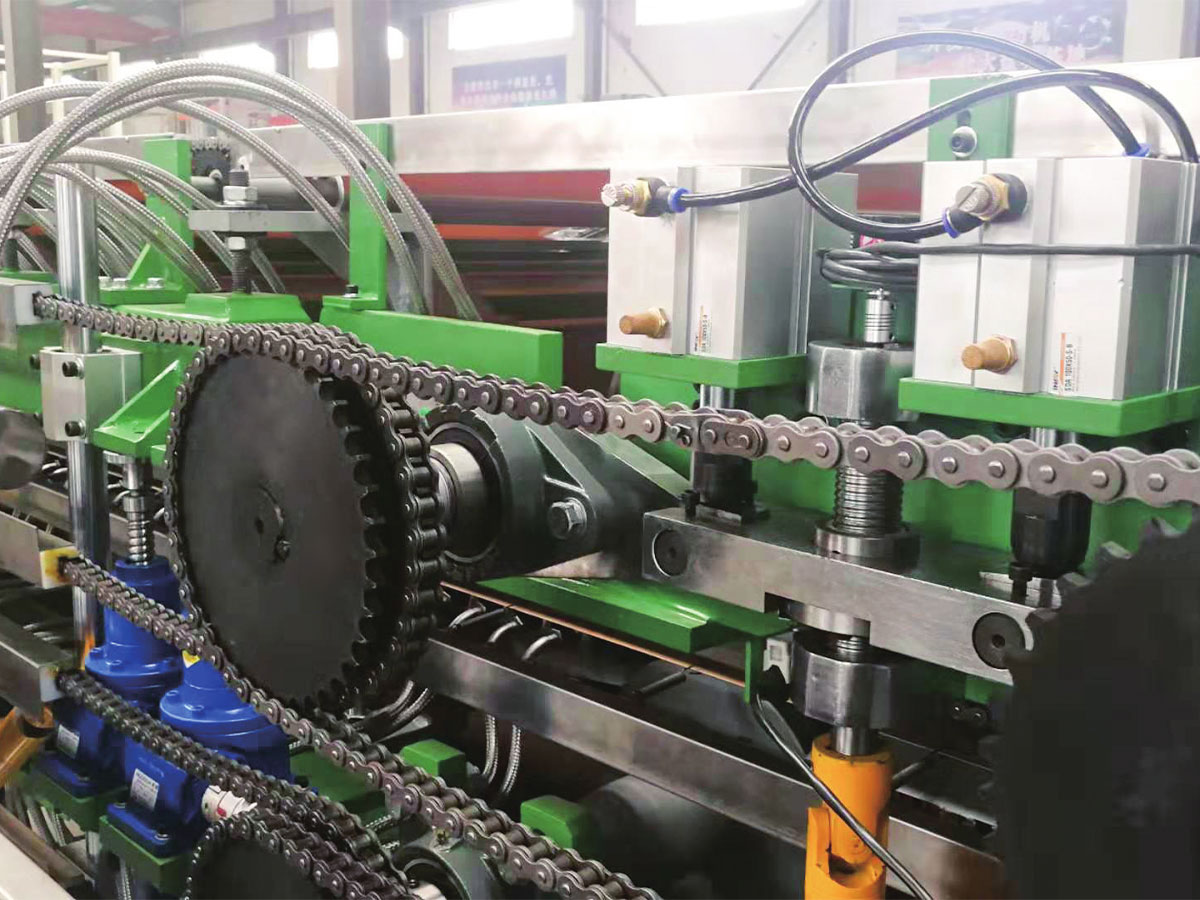

Pretreatment Cleaning Line

The cleanliness of metal surfaces and the quality of chemical conversion coatings directly determine the corrosion resistance, paint adhesion, and final product quality. The chemical conversion cleaning line, as the core equipment in this critical process, uses sophisticated automated processes to thoroughly treat and convert metal workpieces. The pretreatment stage utilizes a multi-stage spray system, first using an alkaline degreaser to thoroughly remove grease and dirt from the workpiece surface. Multiple water washes ensure a residue-free surface, laying the foundation for subsequent processing.

The core of the chemical conversion treatment process involves a precisely temperature-controlled tank system, where the pretreated metal surface reacts with a chemical solution to form a uniform, dense conversion coating (such as a phosphate coating or passivation film). This coating enhances the metal's corrosion resistance and coating adhesion. Post-processing ensures that residual chemical solution is removed through multiple water washes, followed by a final deionized water rinse to ensure an absolutely clean workpiece surface, preparing it for subsequent processing steps. The drying system utilizes a highly efficient hot air circulation device to rapidly remove moisture from the workpiece surface, ensuring complete drying and preventing secondary contamination. A filtration system and automatic refill system ensure the cleanliness and concentration of the treatment solution, ensuring consistent treatment quality.

Pretreatment Cleaning Line

This production line is used for cleaning the surface of the coil and removing the lubricant, grease and other impurities such as silicon, magnesium, iron, copper, etc. Then uniformly apply chromium free treating primer to the front and back of the coil in order to ensure the adhesive strength of the paint. It is an indispensable pretreat-ment process before color coating.

The line we provided for our Spain client is more than 80m/min.

| Coil width |

□1300MM □1600MM □1800MM □2000MM Rollers are 200mm wider than the finished panel. |

| Washing Tank |

□PPR □304 □316L □electrical heating □spray type □immersion type |

| Optional Items |

□Cantilever coil drum type uncoiler, recoiler □Hydraulic splicer □Double arm air inflation type uncoiler、recoiler □Tape splicer □Accumulator □2-roller reaction machine □4-roller reaction machine □Film lamination machine □Automatic coil centering system |

| Material | Aluminum coil:0.15-0.8mm,other thickness can be customized. |

| Speed |

Design speed:40m/min. Production speed:20~25m/min High-speed line can be customized. |

| Line Size | Normal size L: 35M W:6M H:2M, Size is adjustable according to customers’ needs. |

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى