A2/B1 Two-way Metal Composite Panel Production Line

In the field of modern building and decorative materials, market demand for fire safety and versatility is increasing. Our company has successfully developed and launched an A2/B1 dual-purpose metal composite panel production line. This line breaks the traditional limitation of single functionality and perfectly supports the production of both PE/B1-grade composite panels and Class A fire-resistant composite panels, providing customers with a more economical, flexible, and efficient solution.

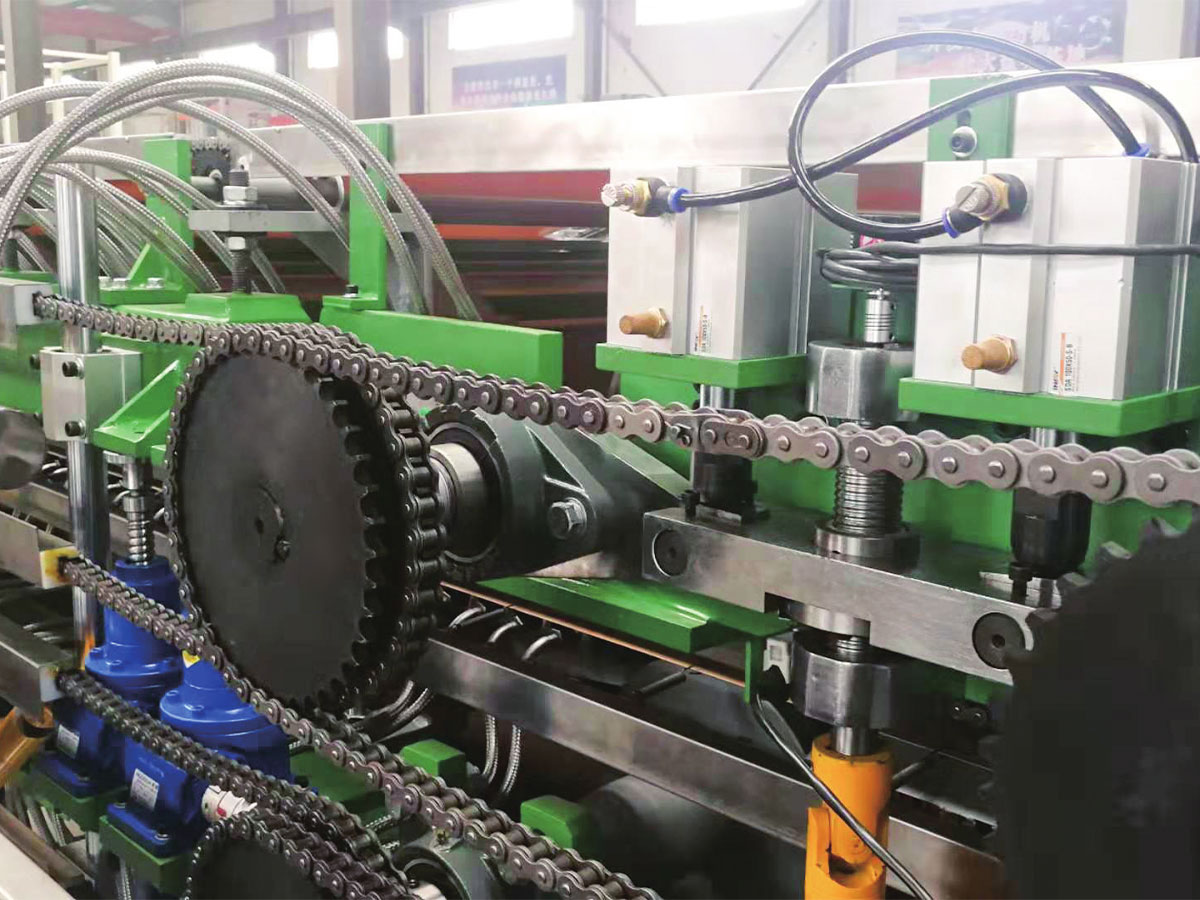

The A2/B1 dual-purpose metal composite panel production line utilizes a precisely designed track and control system, enabling rapid switching between key components.

When producing PE/B1-grade composite panels, the mobile platform precisely positions itself, activating the extruder system to melt and extrude PE or Class B1 fire-resistant plastic granules, forming a uniform core layer that is then laminated with the metal panels.

When producing Class A fire-resistant composite panels, the mobile platform automatically switches to the A2-grade inorganic core material oven and conveyor system, baking and heating the prefabricated A2-grade inorganic fire-resistant core rolls before laminating them with the metal panels under high temperature and high pressure.

This modular, mobile design concept enables a single production line to handle two completely different production processes, eliminating the need for two separate production lines and significantly improving equipment utilization and return on investment. The production line integrates an advanced PLC intelligent control system, automated switching processes, and a user-friendly operation interface, which greatly reduces the difficulty of operation and labor costs, and ensures the stability of the production process and the consistency of the products.

A2/B1 Two-way Metal Composite Panel Production Line

This line is a two-way production line independently developed by our company. The basic theory is to switch the extruder and A2 class core coil oven through moving platform to realize making PE/B1 & A2 class composite panel in one production line.

| Panel Width |

□1300MM □1600MM □1800MM □2000MM Rollers are 200mm wider than the finished panel. |

| Line Type |

□3-roller compositing □2-roller compositing □3&2-roller two-way compositing The above-mentioned is suitable for making a panel of different sizes. Please contact us for more detail information. |

| Oven Type |

□Heating by natural gas, hot air circulation, about 300,000kcal/h □Heating by electricity, new infrared ray type, about 100kw/h |

| Extruder Type |

□Twin conical screw series: □75 type ≦3m/min □85 type ≦4m/min □95 type ≦6m/min □105 type ≦10m/min □Twin extruder series: use two extruders together Note: Every series has its own advantages when using different material. Speed is based on producing 3mm thickness, 1240mm width PE core plate |

| Optional Items |

□Servo-guillotine shear system □Automatic stacker □Double station air expansion type uncoiler □Decorative film lamination machine □MES digital control display screen □Automatic coil centering system |

| Material |

Core material: In A2 panel mode: use A2 class fireproof core coil In PE/B1 mode: use PE/B1 class fireproof granule material

Facing material: Aluminum, Galvanized steel, Stainless steel and other metal coil. |

| Line Size | Normal size: L: 50M W:12M H:5.5M Size is adjustable according to customers’ needs. |

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى