PVC/WPC/SPC Flooring Production Line

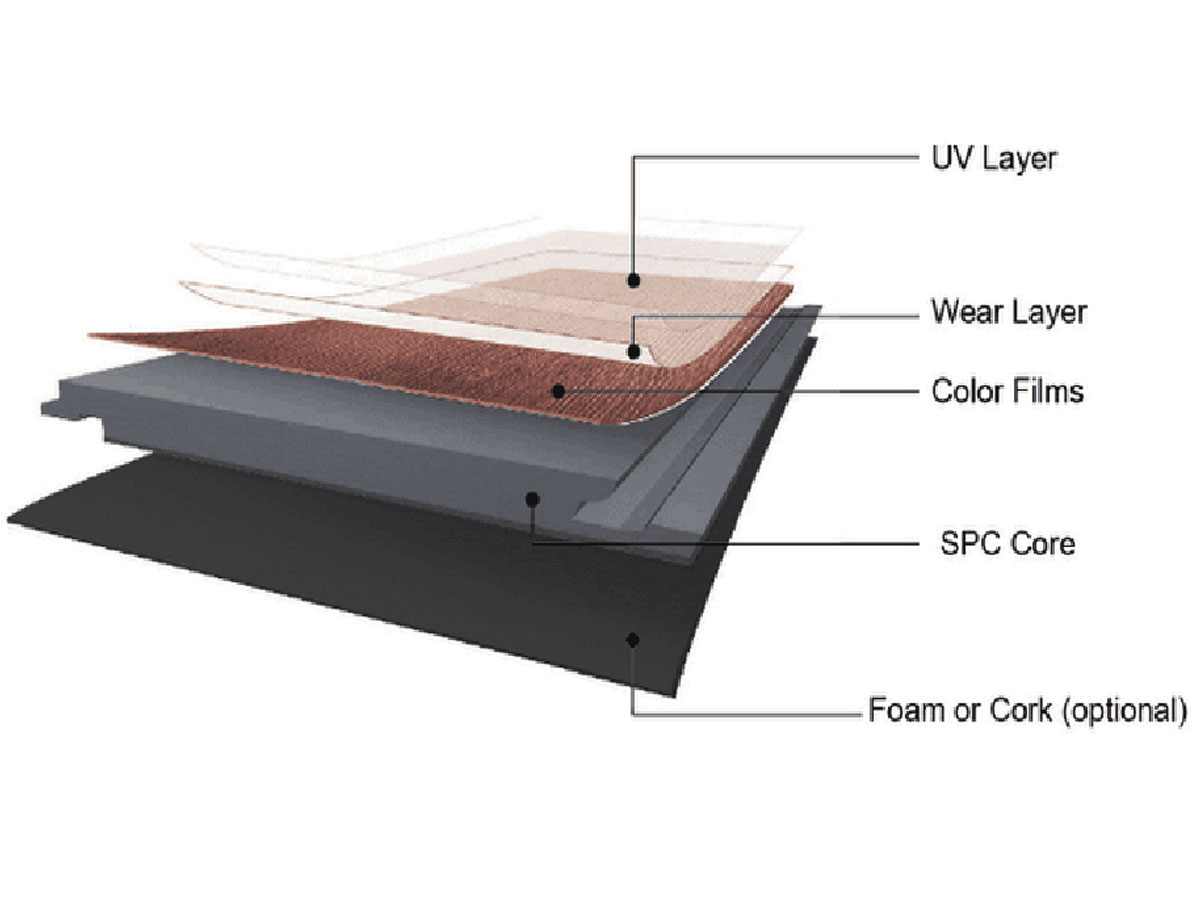

The raw material pretreatment system of the SPC stone plastic flooring composite production line first precisely mixes calcium carbonate powder, polyvinyl chloride resin, and various additives, homogeneously blending them in a high-speed mixer to form the SPC base material. An extruder melts and plasticizes the mixed raw materials under high temperature and pressure, then extrudes them through a die to form a uniform base layer. Advanced T-shaped dies ensure consistent base thickness with an accuracy of ±0.1mm. During the UV coating and decorative film lamination process, the base material surface is first finely treated, followed by a UV primer applied using a precision roller coating system, and then covered with a high-definition decorative film to perfectly reproduce the texture of natural wood grain or stone. During the wear layer lamination stage, the transparent wear layer is firmly bonded to the decorative layer through high-temperature lamination, ensuring excellent scratch resistance. The final embossing process, using a matching embossing roller, creates a three-dimensional texture matching the design, further enhancing the floor's authentic texture.

The SPC stone plastic flooring composite production line integrates a PLC control system and a human-machine interface, enabling fully automated production from feed to finished product, significantly reducing manual intervention. The energy-saving and environmentally friendly design utilizes high-efficiency servo motors and a heat recovery system, saving over 30% energy compared to traditional production lines. No wastewater is discharged during the production process, complying with green manufacturing requirements. Precision quality control, equipped with advanced testing equipment such as online thickness gauges and defect detection systems, monitors product quality in real time, ensuring a product qualification rate exceeding 99%.

SPC Flooring Production Line

This line is for producing SPC flooring.

The basic theory is to extrude the core plate and calendaring, filming, compositing wear layer, and embossing in one step through a four-roller or five-roller system.

Compared with other flooring production processes, it has the advantages of easier operation, higher output, and less waste.

The production line is equipped with a horizontal five roller machine, which can replace the patterned roller more quickly and conveniently, and the operation and maintenance are simple and safer.

The laminate effect of the wear-resistant layer will be better.

The color film and wear-resistant layer can be replaced at the same time without waste.

FULL SET OF SPC PRODUCTION PROCESS AND EQUIPMENT SOLUTION

Material →Loading →Mixing →Extruder →Laminate →Cutting →Stacker →UV coating →Slitting →Grooving →Back foam →Packing

| Calender | □Five-roller series □Four-roller series | ||||

| Plate Size | Length: according to requirement; Width: 975-1220mm | ||||

| Extruder | Screw type | □Twin conical screw | □Twin parallel screw | ||

| Type | □92 series | □110 series | □135 series | □160 series | |

| Output | About 17T/24H | 25-30T/24H | 40-50T/24H | 60-75T/24H | |

| Optional Items | □Auto compounding system □Auto plate turner □Online embossed in register □MES digital control display screen |

||||

| Material | PVC+CaCO3,rate=1:2-3 | ||||

| Line Size | Normal size: L: 35M W:3.5M H:3.7M Size is adjustable according to customers’ needs. | ||||

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى