Color Coating Line

Through automated and intelligent processes, the coating production line provides aesthetically pleasing, durable, and functional surface coatings for a wide range of industrial products. This line, integrating multiple advanced technologies, goes beyond simple spraying operations and encompasses a comprehensive system encompassing pre-treatment, coating, and curing.

The coating production line utilizes a multi-stage cleaning process. First, the workpiece undergoes degreasing, using an alkaline cleaner to thoroughly remove surface grease and dirt. This process is followed by water washing and surface conversion treatments (such as phosphating or passivation) to form a base film that enhances coating adhesion. Finally, water washing and deionized water rinsing ensure the surface cleanliness meets coating requirements.

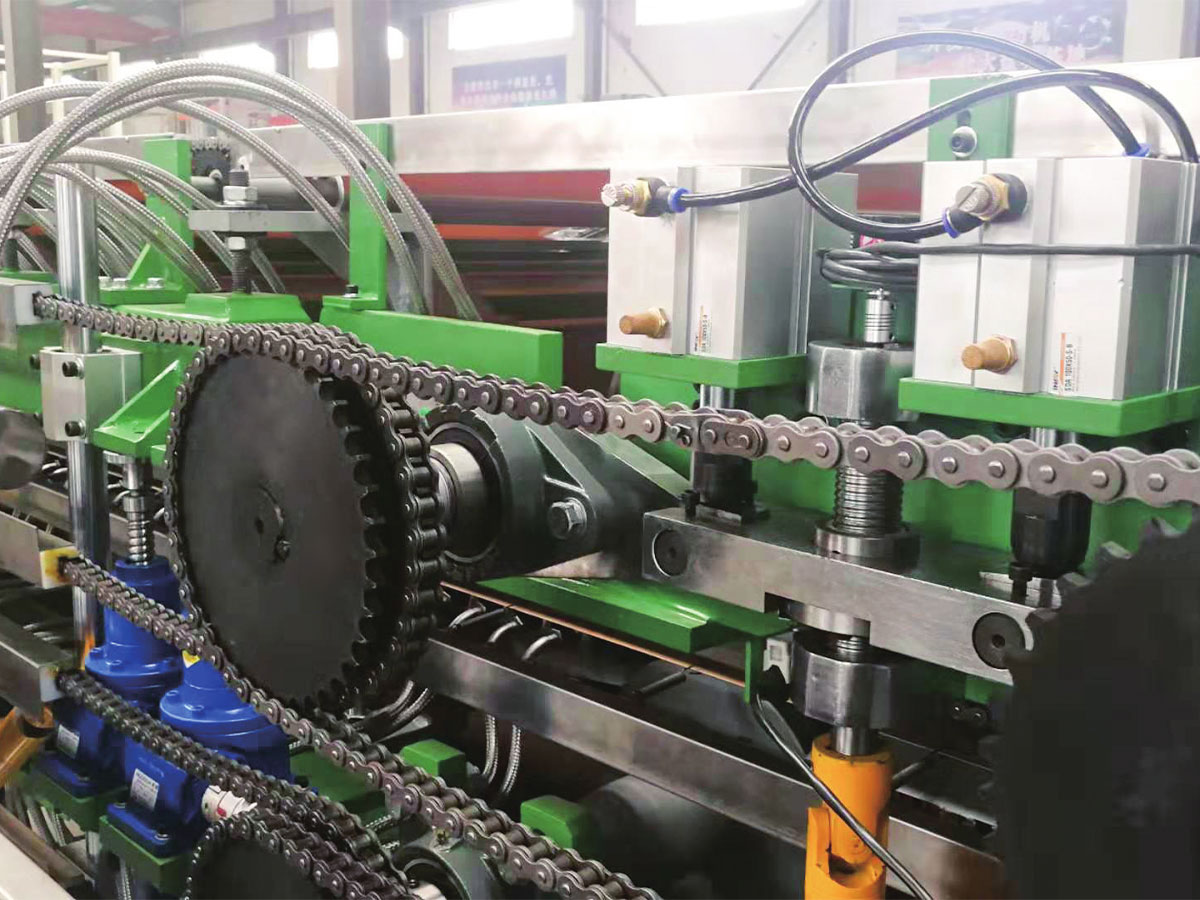

The coating application phase utilizes an automated spray system, using a programmable robotic arm or high-speed rotary cup to evenly apply the coating to the workpiece surface. Advanced electrostatic spraying technology charges the paint particles, effectively improving paint utilization and transfer efficiency. The coating thickness can be precisely controlled by the system. The curing process takes place in a temperature-controlled drying tunnel, where hot air circulation or infrared heating evaporates the solvent in the coating and initiates a cross-linking reaction, forming a strong and durable paint film. The curing temperature and time can be precisely adjusted according to the coating characteristics. The cooling and post-processing stage passes the workpiece through a forced cooling system, followed by quality inspection and necessary finishing operations.

Color Coating Line

This line is for color coating on the surface of the coil.

We developed a precise four-roll converse coating machine at an international advanced level to well control the thickness and appearance. The oven is divided into 4 areas and the temperature in each area can be controlled independently, which will help the solvent resistance, corrosion resistance, hardness and glossiness of the coating reach the best.

We are the first one in China who developed a six-coating & five-baking coating line. By printers in this line, customers can easily print various patterns such as wood, marble, cloth, and so on.

| Line Type |

□Pretreatment □Single coating &single baking □Double coating& double baking □Other customized |

| Coil Width |

□1300MM □1600MM □1800MM □2000MM Rollers are 200mm wider than the finished panel. |

| Oven Type |

□Heating by natural gas, hot air circulation □Heating by electricity, hot air circulation □Heating by electricity, infrared ray type |

| Optional Items |

□Cantilever coil drum type uncoiler, recoiler □Double arm air inflation type uncoiler、recoiler □Double station coater(change color on-line) □Automatic coil centering system □Accumulator □Hydraulic splicer □Tape splicer □Film lamination machine □RTO waste gas treatment and heat recovery system □Embossing machine □Printer |

| Material |

Suitable for PE, Crylic acid, PVDF Aluminum coil: 0.15-0.8mm; other thicknesses can be customized. |

| Speed |

Design speed:40m/min Production speed:20~25m/min High-speed line can be customized. |

| Line Size | Normal size L: 80-100M W:12.5M H:8.5M,Size is adjustable according to customers’ needs. |

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى