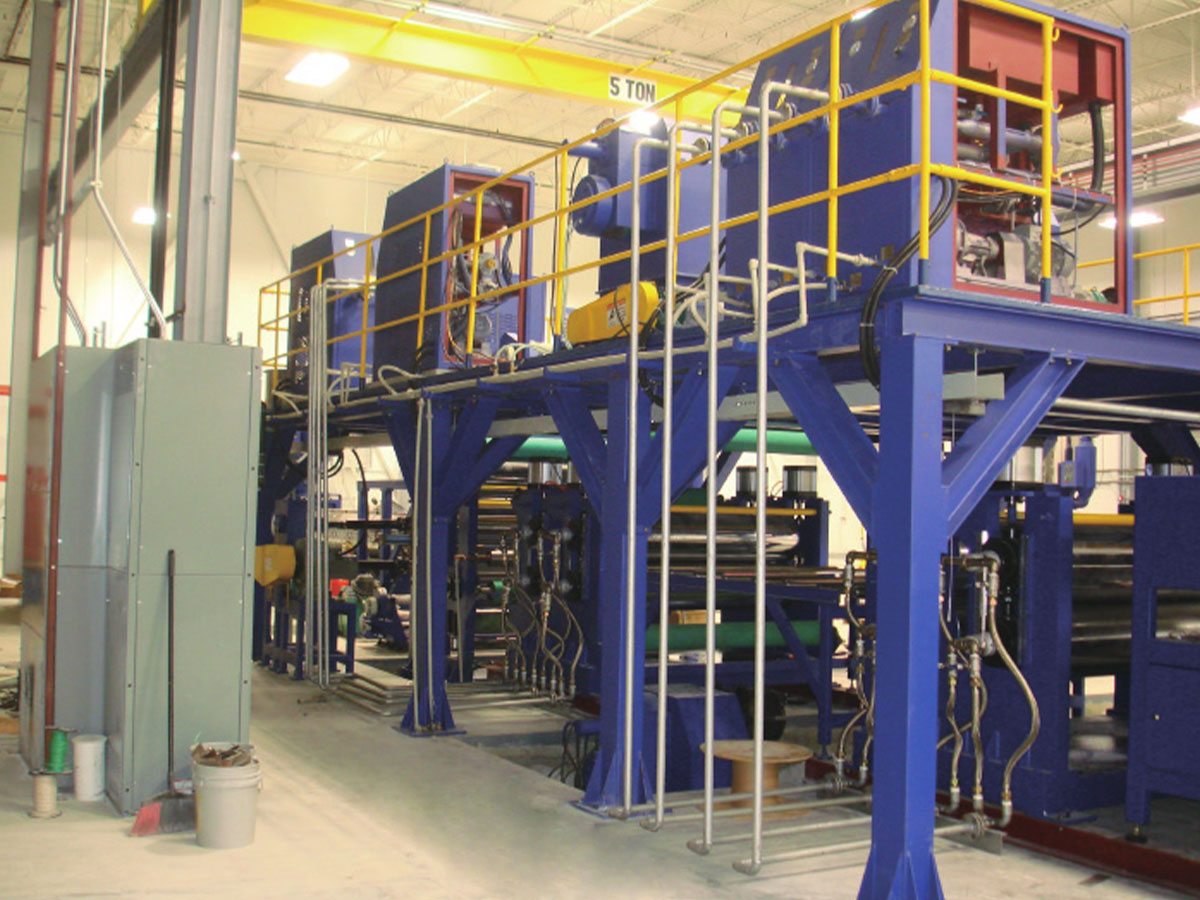

PE/B1-FR ACP Composite Line

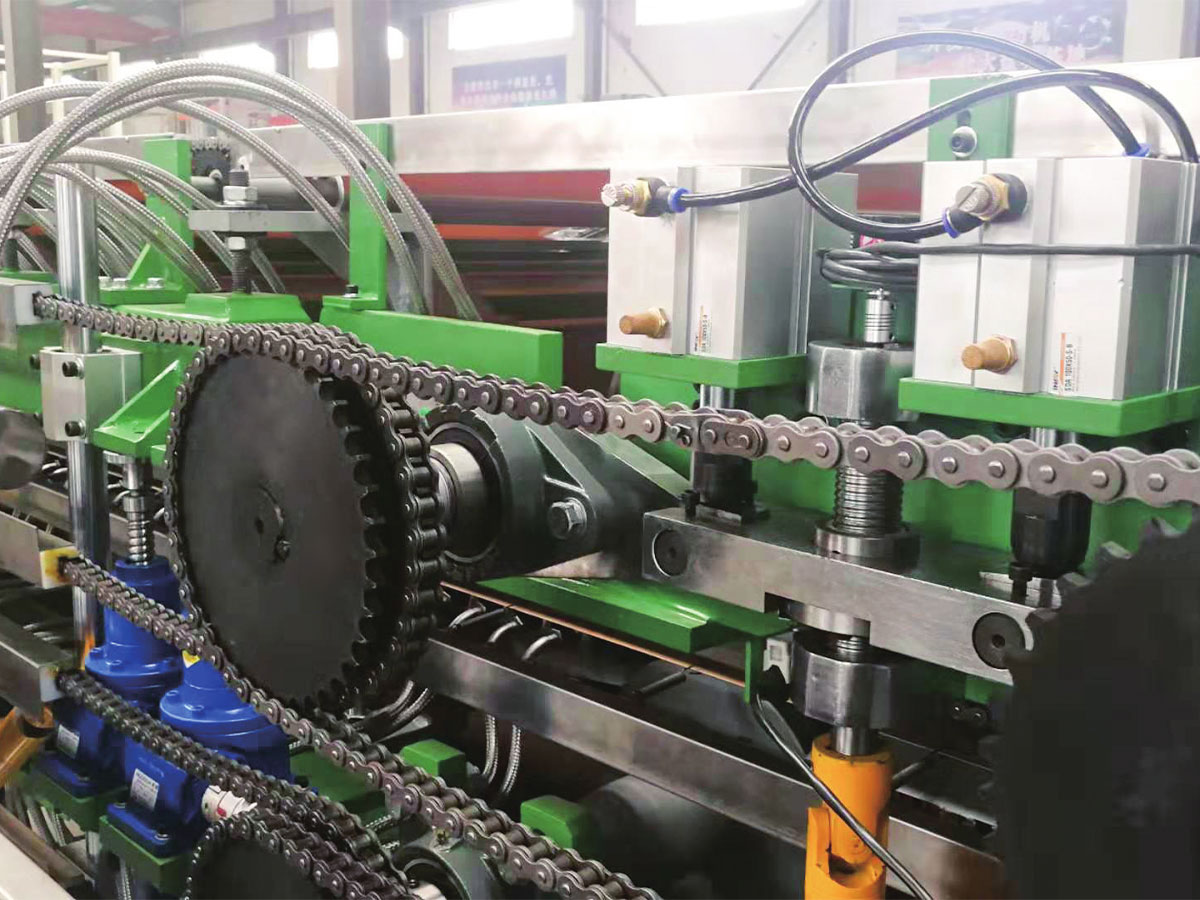

The PE/B1 aluminum-plastic composite panel production line uses a thermal lamination process to firmly bond the surface aluminum coil, polymer adhesive film, and extruded plastic core (such as PE or B1 fire-resistant core material). Its primary function is to produce high-performance composite materials, resulting in aluminum-plastic composite panels that combine aesthetically pleasing decorative features with excellent functionality. To achieve efficient and high-precision manufacturing, the line integrates automated control systems (such as PLC) and high-precision actuators (such as magnetic powder tension control and cut-to-length cutting), enabling continuous automated production from unwinding, lamination, and cutting, improving production efficiency and product consistency. The PE/B1 aluminum-plastic composite panel production line melt-extrudes the core material (such as PE or B1-grade fire-resistant particles) through an extruder. The extruder then laminates the core material (such as PE or B1-grade fire-resistant particles) with the surface aluminum coil and polymer film through high-temperature roller pressing. Finally, the sheet is cut to length. This high-temperature roller pressing ensures a secure bond between the core and the metal surface material, imparting excellent flatness and bonding strength to the panels.

The line offers various lamination methods:

Three-roller lamination series: Suitable for high-standard flatness requirements. Two-roller laminating series: Balances efficiency and cost-effectiveness.

Three-roller/two-roller universal laminating series: Flexible adaptation to diverse production needs.

Aluminum Composite Panel Production Line For PE/B1

This line is for making PE/B1 class aluminum composite panel. The basic theory is to composite aluminum coil, high polymer film and core material from extruder under the pressure of high-temperature rollers, and cut it to the required length. We upgraded the 2nd, 3rd, 4th generation line referred to the advantages of the 1st generation lines from Germany, and invented 2-roller compositing, 3&2-roller two-way compositing technique. Not only improved the operation and use performance, but also regarded as the original productions in the industry.

| Line Type |

□3-roller compositing □2-roller compositing □3&2-roller two-way compositing The above-mentioned is suitable for making panel of different sizes. Please contact us for more detail information. |

| Panel Width |

□1300MM □1600MM □1800MM □2000MM Rollers are 200mm wider than the finished panel. |

| Extruder Type |

□Single screw series: 180 type ≦2m/min □Twin conical screw series: □75 type ≤3m/min □85 type ≤4m/min □95 type ≤6m/min □105 type≤10m/min Twin extruder series: use two extruders together Note: Every series has its own advantages when using different material. Speed is based on producing 3mm thickness, 1240mm width PE core plate |

| Optional Items |

□Servo-guillotine shear system □Automatic stacker □loss-in-weight feeder □Double station air expansion type uncoiler □Decorative film lamination machine □MES digital control display screen □Automatic coil centering system |

| Material |

Core material: PE,/B1 class fireproof granule material; Facing material: Aluminum, Galvanized steel, Stainless steel and other metal coil |

| Line Size | Normal size: L: 50M W:12M H:5.5M Size is adjustable according to customers’ needs |

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى