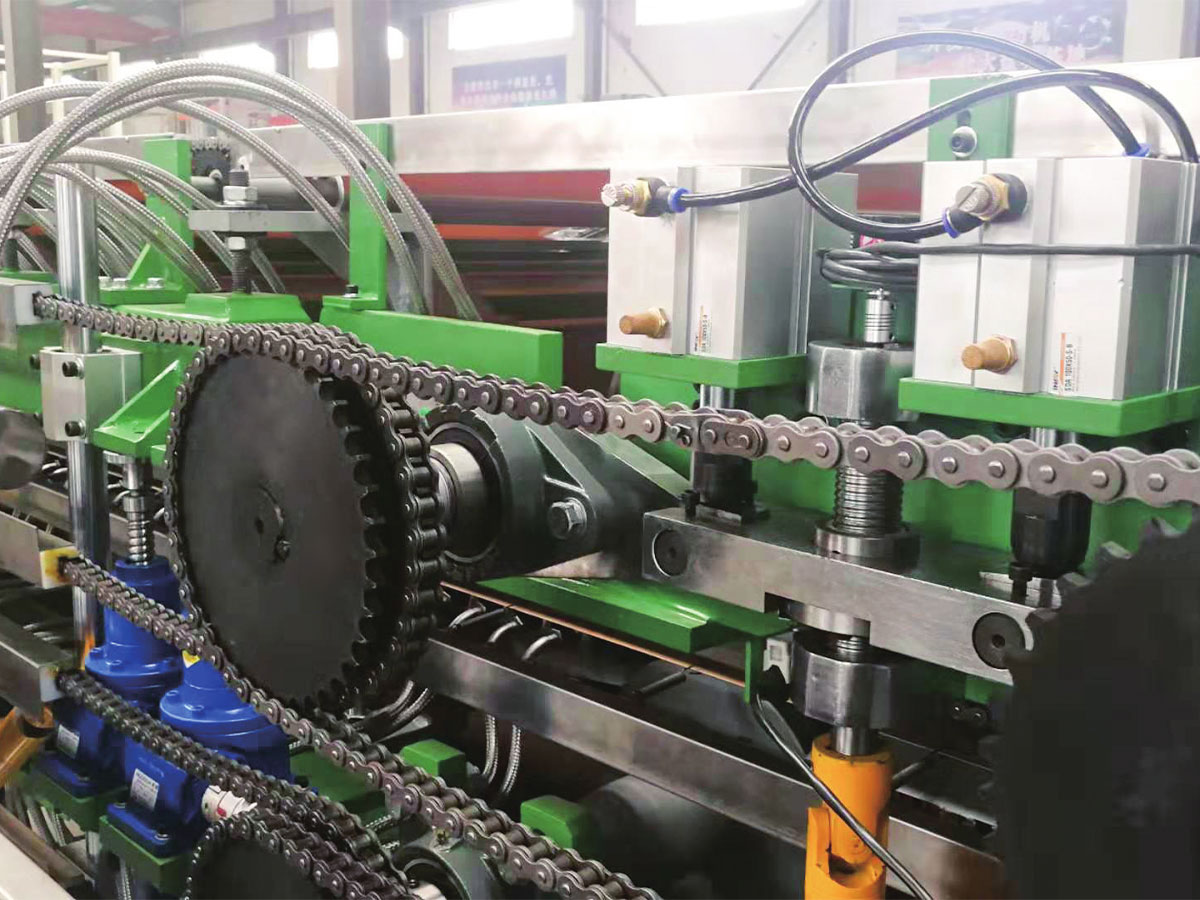

Embossing Machine

Product introduction:

The embossing machine presses various three-dimensional patterns on the surface of the board through precision pattern rollers. It can not only imitate the delicate texture of natural wood and the rough texture of stone, but also create a variety of unique geometric patterns. More importantly, these uneven textures not only enhance the aesthetics of the product, but also increase the rigidity and deformation resistance of the board through structural reinforcement.

Advantages and features:

Strong three-dimensional sense and decoration: The core advantage is that it can quickly press long-lasting and exquisite three-dimensional patterns on the surface of the board, which greatly enhances the beauty and added value of the product.

High precision and long life: Use high-precision processed rollers to ensure clear, consistent and repeatable patterns. After heat treatment and surface strengthening, it is wear-resistant and durable and has a long service life.

High degree of customization flexibility: Both the width and embossed graphics can be customized according to customer requirements, which can meet the diversified and personalized design needs of the market and is highly adaptable.

High production efficiency and easy operation: The equipment has a high degree of automation and can achieve continuous, high-speed production. The operation process is simple, which helps reduce dependence on skilled workers and improve overall output.

Application areas

Building decoration industry: used to produce decorative wall panels, partitions, ceiling panels, etc.

Furniture manufacturing industry: used for decorative embossing of cabinet doors and furniture panels.

Packaging and advertising industry: used to produce high-end packaging boxes, display stands, advertising backboards, etc.

Mainly used for embossing 3D, corrugated core.

- high precision roller, long useful life

- easy operation

- width, pattern can be customized

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى