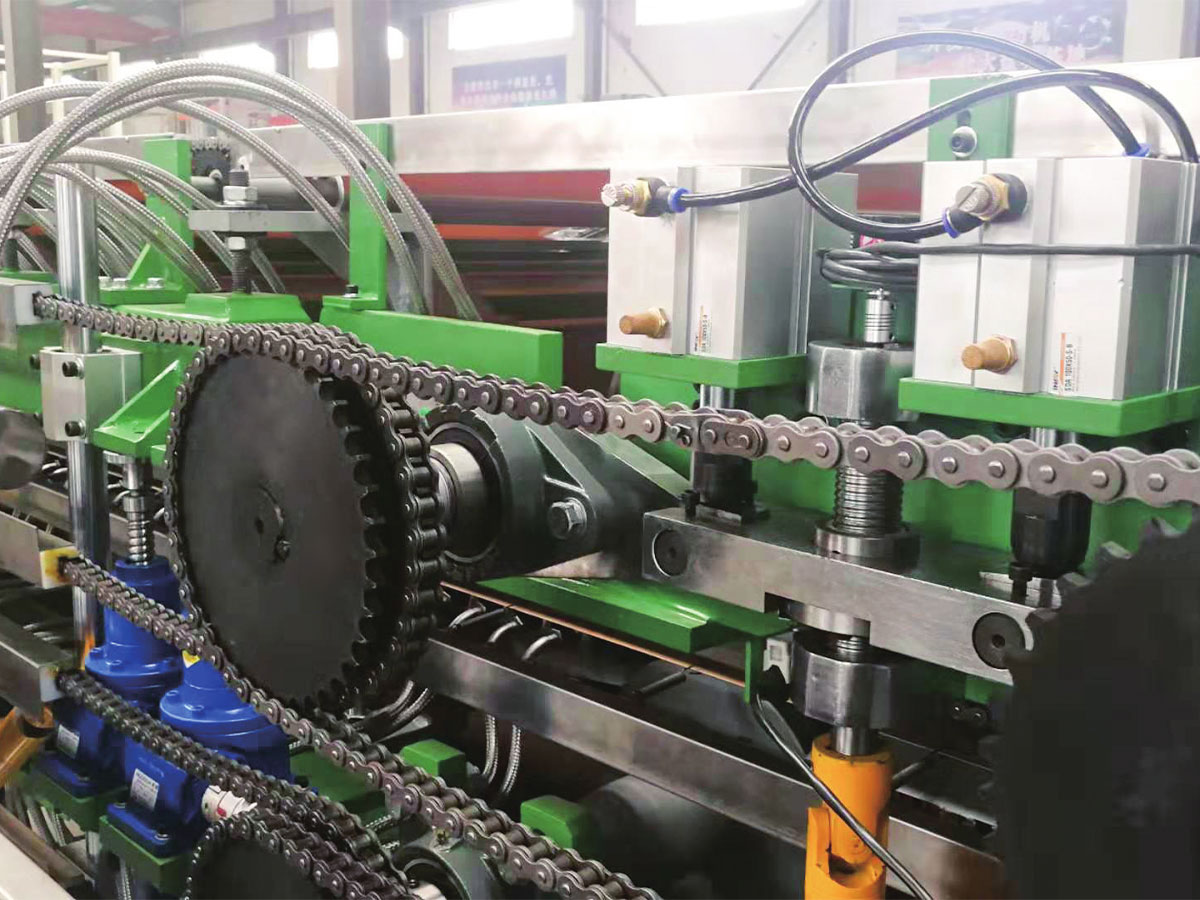

Three-roller Levelling Machine

Product introduction:

The three-roller leveling and forming machine can repair the internal stress, warpage and unevenness defects caused by the plate during the preliminary processing. This equipment applies a precisely controlled rolling leveling force to the metal sheet, causing the molecular structure of the sheet to plastically deform and regain a perfectly flat state. The high-strength alloy steel rollers of the three-roller leveler are arranged in an isosceles triangle, in which the upper roller is an active pressure roller and the two lower rollers are driven support rollers.

Advantages and features:

Dual-purpose machine, strong functionality: The core advantage is that it can not only perform high-precision leveling of plates, eliminate internal stress and unevenness, but also complete rolling/arc forming. It has high functional integration and wide applicability.

High-precision and high-quality molding: By adjusting the precise gap between the three rollers, the flatness after leveling or the roundness and consistency after rolling can be effectively ensured, and the molding quality is stable and reliable.

Powerful customization flexibility: The size, material and surface treatment of the rollers can be customized according to the material, thickness and molding requirements of the customer's workpiece to meet diversified production needs.

Stable structure and durability: The equipment usually adopts heavy-duty steel structure and high-strength rollers, which can withstand continuous heavy-load processing and has a long service life.

Application areas:

Sheet metal processing and manufacturing: used for leveling and rounding of chassis cabinets and various equipment casings.

Chemical and energy equipment: used to make ventilation ducts, dust removal ducts, tank heads, etc.

Building decoration industry: used for forming aluminum plates and stainless steel plates such as curved roofs, curtain walls, decorative columns, etc.

Elevator and transportation: used for processing of elevator car curved wall panels, vehicle shells and other components.

Mainly used for Aluminum composite panel,

Aluminum sheet, Stainless sheet levelling.

- roller clearance adjustable

- size can be customized

*E-mail: grammy@cjm.com.cn

grammy@cjm.com.cn

grammy@cjm.com.cn

English

English русский

русский Español

Español عربى

عربى